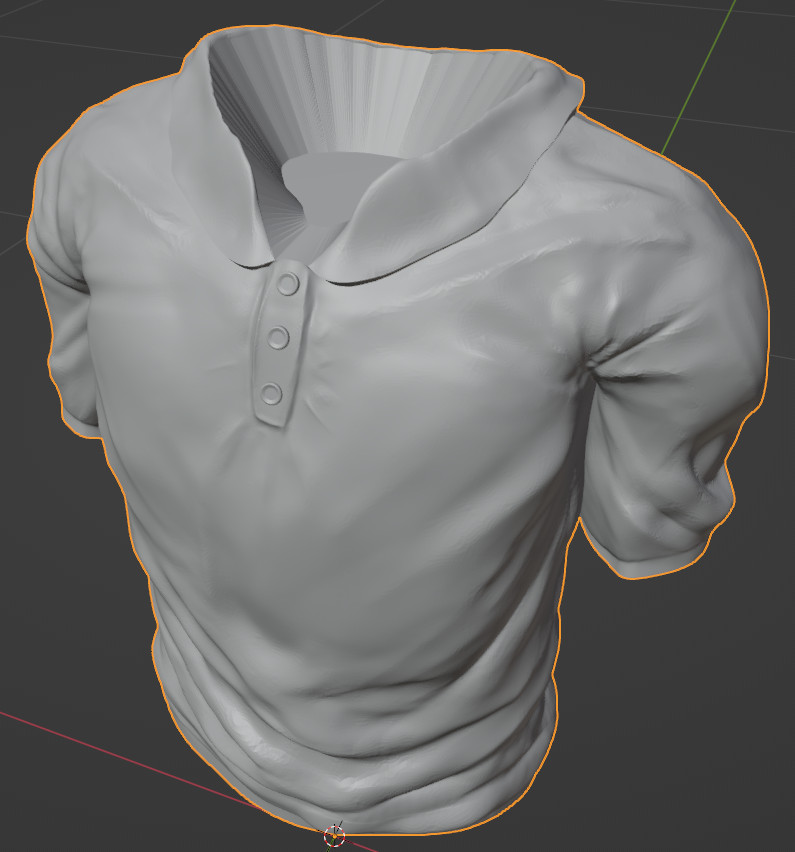

Until now we have kept our MSG in a plastic bag in a cupboard held shut with a paper clip. My wife and I are fans of Nigel Ng and particularly like his Uncle Roger videos, so my brother Morgan Jones and I made her an orange-polo-shaped MSG shaker as a gift for her birthday. Morgan did all of the hard work on this project very quickly, but this is just a small sample of the kind of things he does. You can see his other work on his website and Instagram feed.

Morgan created the polo shirt model using ZBrush and then taught me some tricks to clean it up for printing in Blender. Most of my experience in CAD has been as an engineer using solid modeling tools like AutoCAD and Creo, but those tools do not work for a project like this for a couple of reasons:

- Complicated geometries can slow editing down a lot

- Converting a mesh into a solid object is a rare and costly feature

Major-league CAD programs like Creo have tools that convert mesh files into solid models, but that conversion is always slow. FreeCAD has a pretty good tool, especially considering it is free, but it wouldn’t have been able to convert this shape even if I let it run for days.

I currently do all my mechanical CAD work in OnShape and FreeCAD, but I have recently started using Blender for editing complex meshes. I am still ignorant of about 99.9% of what Blender can do, so I really appreciate the tutoring.

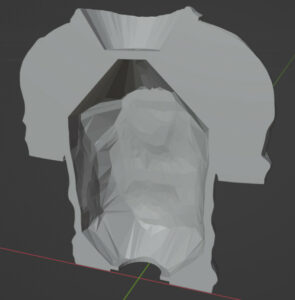

After cleaning up the model, I shelled the inside and manually cleaned up the interior geometry for printing. The only internal geometry that requires support was the very top in the neck where the pouring holes were, and that is deliberately positioned right over the filling hole in the bottom so that the supports can be pulled out without leaving plastic scrap inside the shaker. This has the added benefit that the inside of the container is funnel-shaped, so none of the MSG can get stuck inside and wasted.

The finishing touch was to inscribe “KING OF FLAVOR” in the back, which is parameterized so that it can be altered for different languages.

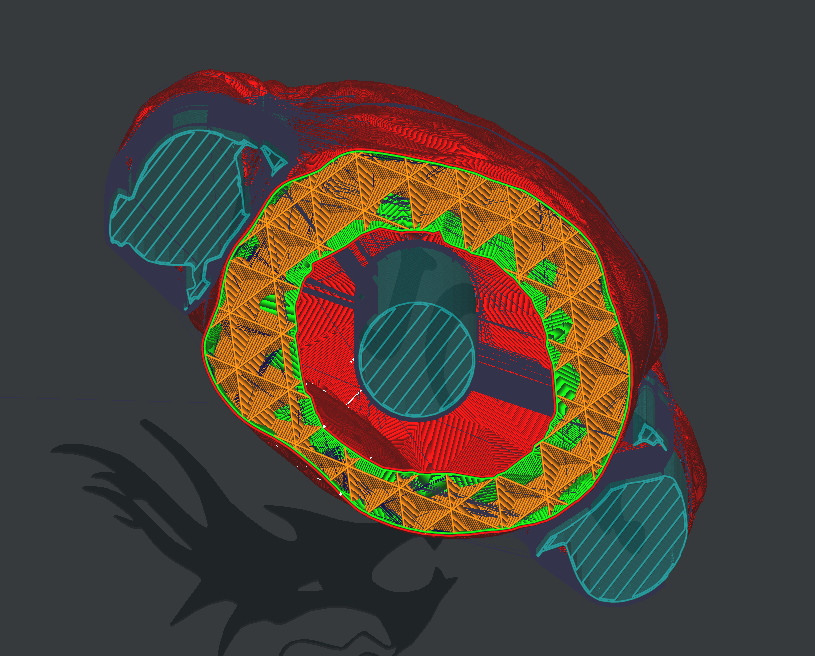

The plug fits in snugly and the shaker is able to hold about 8 oz of MSG. MSG crystals are bigger than grains of salt or pepper and don’t pour easily out of a salt or pepper shaker, so I made the holes big enough to handle the grain size without clogging.

This kitchen device is used to store dry materials at room temperature, so I printed this model in PLA. PLA is not suitable for wet, warm, or abrasive things, so it generally isn’t used for food-safe applications. I am currently working on a 3D-printer enclosure so that I can print more of these out of ABS. EDIT: There is no easy way to produce a 3D printed part that could be considered food safe but regulatory agencies. ABS and other materials that can be smoothed have a distinct advantage in food applications because they can be cleaned more easily when they are smooth, but there is always concern about leaded brass in nozzles, loose plastic fibers in the interior, and steps along the filament production and storage process. This is storing a dry solid at room temperature, so I am not concerned about it for personal use.

You can find the files necessary to print or modify this on Thingiverse here.