Over the last couple months I have been brewing a triple-berry hard cider from ingredients easily available at the grocery store. I loosely followed an easy recipe that I have used before, but this time I kegged the cider in a kegerator I bought on Facebook marketplace instead of bottling it, which was much easier.

The flavor of an apple cider is usually balanced by creating a mixture of apple varieties. For example, a cider maker might mix crab apples, Granny Smith, and red delicious in some proportion to get the flavor they are going for. That is honestly too much work to do at home, since it would require not only getting a mixture of about 60 pounds of different types of apples, but also juicing and pasteurizing 5 gallons of apple juice. To do it right would require a juicer or juice press, a sizeable strainer a 5-gallon stock pot and probably an outdoor burner, since a 5 gallon stock pot won’t fit on most stoves. For this cider, I am adding three types of berries that will pretty much drive away the apple flavor, so I think it is totally appropriate to use pre-mixed, pre-pasteurized apple juice.

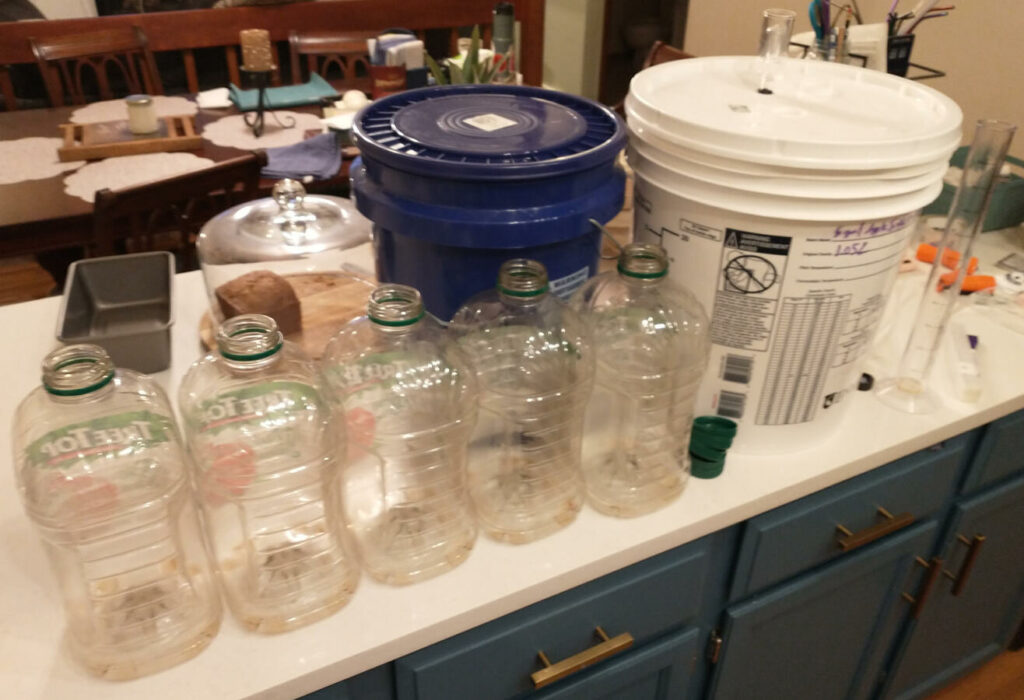

I bought 6 gallons of Treetop apple juice for about $36 and 2 3-pound bags of frozen mixed berries from Costco for about $15. I also ordered a 10-pack of champagne yeast from Amazon that came out to about $1.50 per envelope. It’s a little more expensive than making beer, but apples are more expensive to grow than grains, so it makes sense. To do this on the very cheap scale, you could also use juice concentrates, which I will do for a future project. Two other important ingredients are around a couple tablespoons of pectic enzyme, which will keep the pectin in the berries from clouding the cider, and about a cup of erythritol for sweetening.

I use erythritol as a sweetener over other sweeteners because it has almost no flavor and is not toxic to dogs. If a glass of cider falls on the ground or I spill some during brewing, the dogs are going to try to lick it off the floor and I want it to be safe for them.

Since the juice is already pasteurized, the first step was just to sanitize my primary fermentation bucket and pour 5 gallons of apple juice, the pectic enzyme, and the activated yeast into it. I kept some of the juice and poured it into a cylinder to measure the specific gravity, and determined that there was enough sugar in the mix for the yeast to produce a final result of about 6% ABV.

I always hydrate yeast in water that I have recently boiled, but this time I think I may have burned the yeast. Either that, or maybe it was harmed when our refrigerator died last year. Since I didn’t see bubbles for a few days, I opened another packet and added it to the mix, at which point the fermentation took off as expected.

After over a week had passed, I sanitized a big pot and a cheesecloth sack to hold the berries while they defrosted. These frozen berry bags often have small holes from bumping against each other, so I tried to keep them from thawing in the bags. All of the berry juice and the sack of berries went into the fermenting bucket, and I squeezed the bag to get as much juice out of the berries as possible. The berry juice has slightly higher sugar content than the apple juice, but it’s not enough juice to significantly increase the alcohol content. The first time I used this recipe I re-measured and found that it would land somewhere between 6% and 6.5% at most.

I left this mixture sitting in the primary fermenter for a couple weeks, then transferred it to a glass carboy for secondary fermentation. I tried to use an in-line filter, but I would not recommend it. I think that the fine filter that would be required to actually remove the precipitate would render a siphon mostly useless, so in the future I will just do it the old-fashioned way and lose the little bit of cider with the precipitate in it.

After a month or so I racked the cider into another carboy prior to kegging to remove more of the precipitate. I have an unrefined palette, so I gave my wife a glass of cider and a bag of erythritol and she figured out how much to sweeten it by, which I then scaled up for 5 gallons. I boiled water on the stove to make an erythritol syrup, let that cool down, added it to the new carboy, and mixed it into the cider.

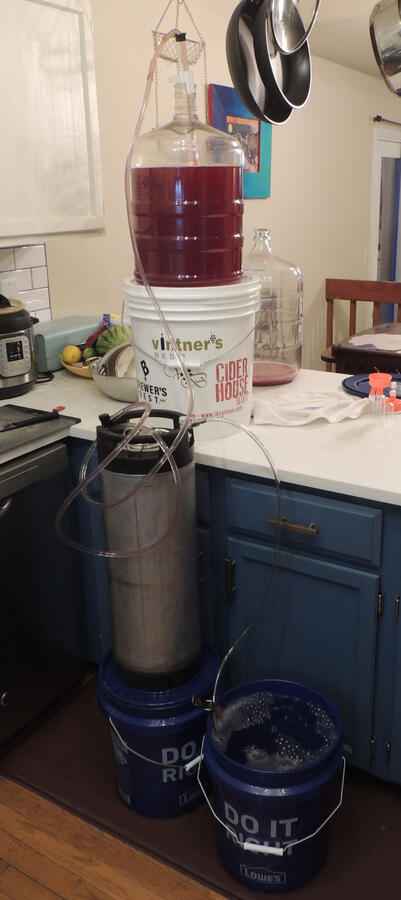

To sanitize a soda keg like this, I filled it to the brim with my sanitizer and let it sit for an hour or so. Then I filled it with CO2 from the CO2 tank, pushing the sanitizer out of the keg and back into a storage bucket. The result is a keg that is full of CO2, not air that could oxidize the cider.

I set that keg up on a 5-gallon bucket on the ground, put the cider carboy on a 5-gallon bucket on the counter, and fed a blowoff hose from the keg into a bucket of sanitizer to form an airlock. Since I had already racked the cider, I just set the siphon down and walked away for about an hour. The openings on the ball lock fittings are much smaller than the hose I normally use for siphoning, so it takes a while to move the cider with just gravity. I designed a holder for my wine thief that clips on and holds it at a consistent depth from the nozzle of the carboy. You can find that design on Thingiverse here. It doesn’t work extremely well, but well enough for this purpose.

Once that was all done, I took the keg downstairs to the kegerator and hooked it up to the CO2 tank at about 16PSI. I will tune that in later to get it almost as fizzy as a soda.

The last step was to clean out all the taps and replace the lines on my used kegerator. After I replaced the lines, I had to run sanitizer through them, so I designed a dummy insert for Cornelius keg ball lock fittings that I could 3D print and use to hold open the valve in the ball lock fitting while I siphoned sanitizer through the lines and tap. You can find the STL files for that part on Thingiverse here.

Now that it has been a few days, the cider is carbonating nicely and is very tasty. This is my third time using this recipe, and I think this is pretty close to perfect. I’ll have to try some new things with the next batch.