Closet doors are often built with dummy doorknobs that look and feel like a normal doorknob without the internal pieces that would rotate and move a latch. They usually look just like the normal handle but they can only be installed on a door without a hole because you use wood screws to fasten them straight to the wood. So what do you do when you want a dummy doorknob but your closet door already has a regular one? I designed this adapter to turn a regular doorknob into a dummy knob that doesn’t rotate when you grab it.

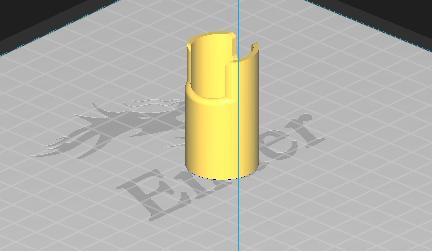

In our house, all the closets were installed with passthrough door knobs, which is the normal kind where there is a knob on both sides and they turn together. Those knobs started to jam up around 40 years after they were installed, and I wanted to replace them with dummy doorknobs to eliminate the chance of jamming. After playing with it, I also decided that I didn’t want the knob to rotate freely. In my opinion, the dummy knob is more mechanically satisfying when it feels nice and solid and does not rotate, but that also complicates the geometry.

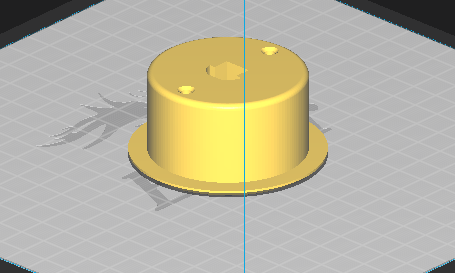

I measured out the hole and made a test plug, but found that the friction from the screws clamping down on the door did not provide enough force to prevent the entire assembly from turning when I grabbed the knob and twisted, which is a muscle memory that I have not unlearned. To fix that issue, I made a new version with an insert that locks the rotation of the insert.

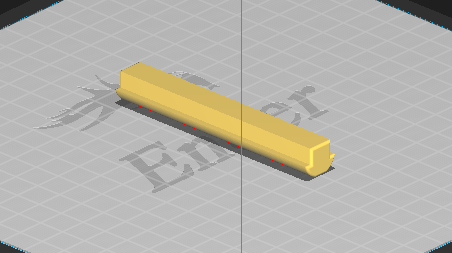

This design is compatible with Kwikset knobs, but could be modified for other interfaces just by changing the profile and length of the key.

These pieces will work just fine if printed in PLA, but could be made stronger by printing in a material with higher yield strength like PETG. The key shaft is a separate piece so that it can be printed laying flat. That way, that the shear stress is normal to the printing layers and it will not shear when someone aggressively turns the knob,. The parts should all print without supports in these orientations:

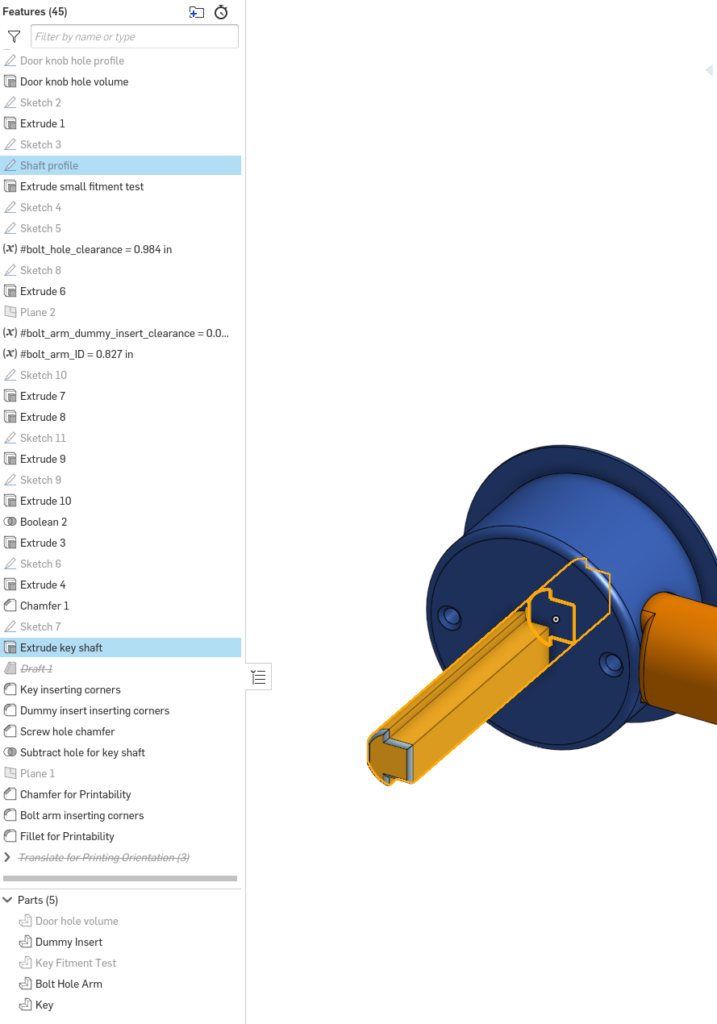

These files are available on Thingiverse here. To modify the interface geometry for other types of knobs, fork my Onshape project and modify the “Shaft profile” sketch and “Extrude key shaft” extrusion as necessary.