I bought a PineTime smartwatch a long time ago, and started using it more recently. I charge it next to my bed, and the charging cradle would occasionally end up on the floor with the watch disconnected in the morning. The PineTime charging cradle is very nice, but I was starting to get jealous of the Apple Watch accessories. I wanted some way to hold the watch charger in place at an angle where it can function as a clock someday when the firmware supports it.

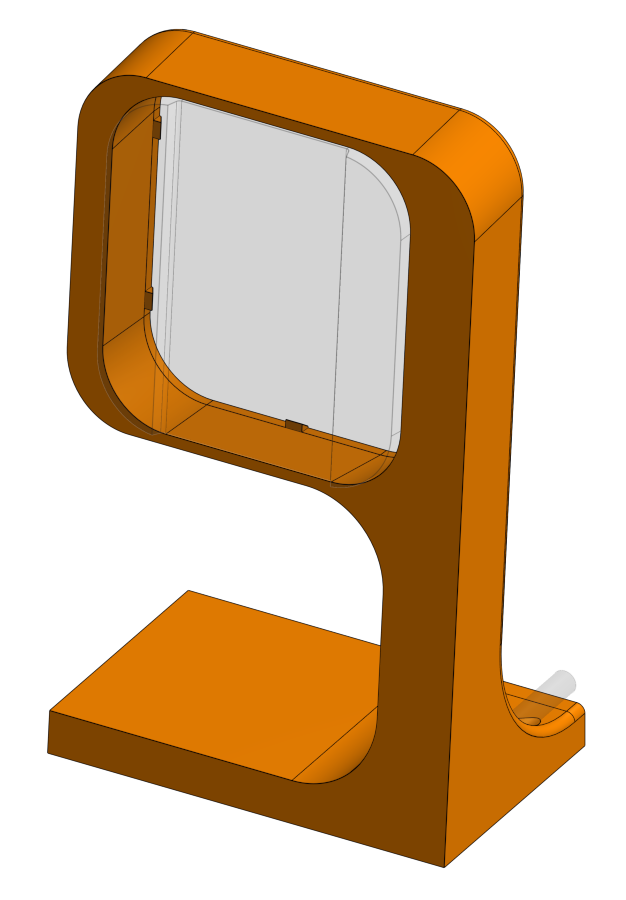

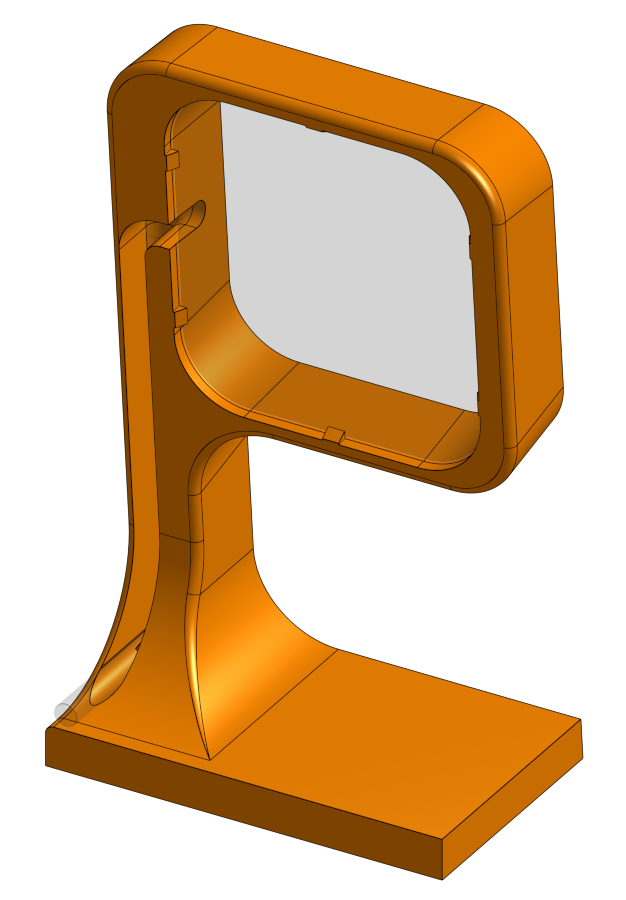

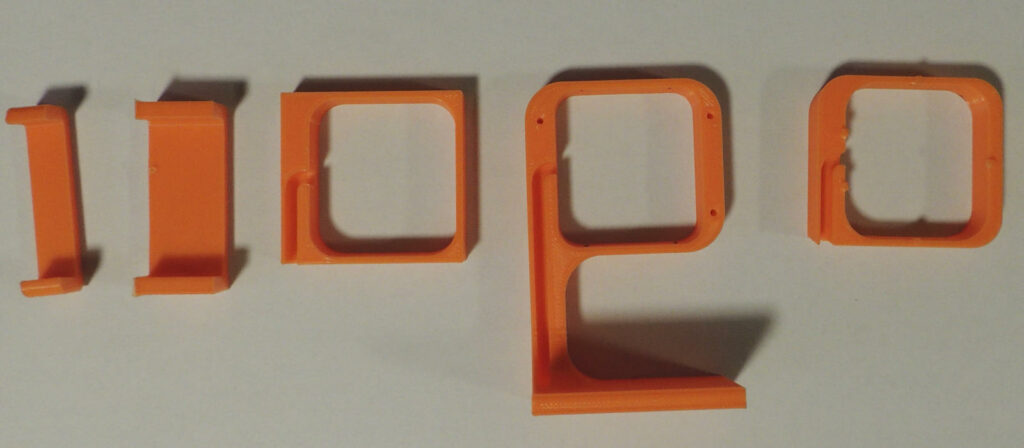

I couldn’t easily find a good model of the charging cradle online, so I drew a pretty good approximation of it in Onshape and 3D-printed some test fixtures to dial in the dimensions.

The draft angle on the sides of the cradle is only about 3 degrees, and is probably there just because of the injection molding process, but it’s the best option for interfacing with the part I could think of without using fasteners. After a few tries, I got it to snap in from the back with some retaining clips to hold it in place. I printed this in PLA with 20% infill, and the plastic is flexible enough that I could take it apart again without damaging the cradle or the stand.

Since I wanted this to be a pretty clock, I didn’t want to have a USB cable coming out of it at a weird angle. Instead, the USB cable is routed inside the part the same way I did for my Steam Deck dock. At the end of the cable’s path there is a little nub to retain it.

The main problem I was thinking about is that the whole stand would be top-heavy and fall over, but a lot of those problems happened to be fixed just by luck. The balance between the watch body and the strap just happens to be in the right place, and the bottom strap just happens to rest on the table at this height, which relieves some of the weight from the back.

One thing I did not consider that led me to do a revision is that the upper watch strap would press down on the top of the stand with enough leverage to lift the watch out of the cradle a little bit. To fix that, I drafted the surface where it made contact to present a much smaller profile and tested it. It still has the potential to apply enough force to move the watch, but only a tiny bit and only if the little strap loop happens to be right in the way.

If you like this design and want to print it yourself, you can find the STL files over on Thingiverse. It should print just fine without supports on an FDM printer with the front face down. You can also fork my design on Onshape.