In the winter, the window well right next to my desk tends to fill with snow, and the area near the window where I work becomes unpleasantly cold. Our house had steel mesh window well covers to keep animals out, but this year I decided to replace them with clear polycarbonate covers.

Our window wells are fairly old and busted. Due to some mistakes during their installation, they are slightly bent with about an inch of variation of any given dimension between them. The covers that were installed when we moved in were basically sheets of expanded steel mesh, the kind you would stretch over a stair step for traction or make a durable security screen from. The mesh was cut to the right shape, left with the jagged edges, and then screwed to the window well. They were simple, cheap, and effective, but definitely not safe.

Due to changes in building code, they no longer legally provide egress points from the basement, since they aren’t deep enough to allow someone wearing an oxygen tank to climb down. That is probably why the previous owner thought that it was okay to permanently block them by screwing a wire mesh in place over the opening. They could easily function as an escape route in an emergency, though, so I was determined to use covers that could be opened easily from inside or outside.

After a long time of looking for reasonably-priced polycarbonate sheets, I realized that the only sensible thing to do was buy prefabricated window well covers and modify them to my needs if necessary. I was able to get one that would fit for not much more than the cost of just the plastic.

The installation hardware was intended to give you the option to lock the window from the inside either for security or strong winds. The idea is that you would bolt brackets around the inside edge of the well, then drill matching holes in the plastic and put cotter pins through the plastic sheet and brackets. You would then have the option to put lock rings on the pins for security. With so many pins, the cover would be kind of hard to remove, and if it rested on the well edges it wouldn’t slope away from the house at all, so I made some changes.

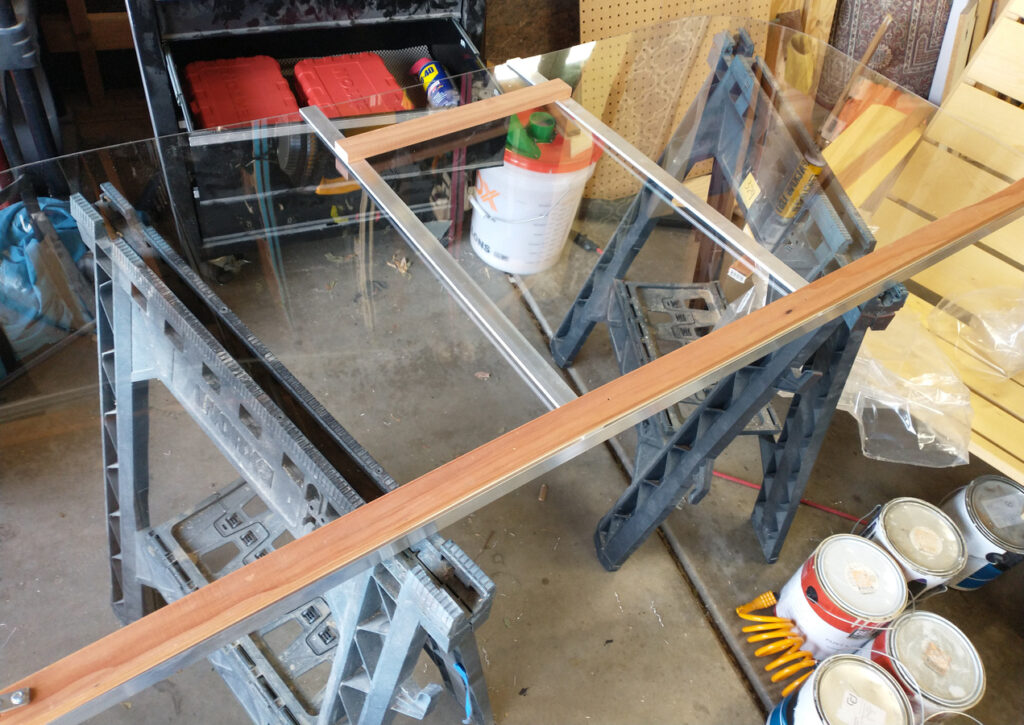

I decided I didn’t like the manufacturer’s installation method because it was too hard to open and didn’t slope the sheet away from the house at all. Instead, I used some furring strips we had around and two of the brackets from the manufacturer’s kit to make the interface.

With the furring strip lifting the back edge, the cover should be sloped away from the house about 2 degrees. It is held in place snugly against the well wrap so that it just lifts out of place easily. The back edge is just behind the point where water would run off the siding so that we will rarely get water dripping down into the well.

I had a theory that adding the window well covers, even with the small air gap to allow some airflow in and out of the basement, would provide some amount of insulation for these windows. Most of the air mass in the window well will not be able to mix easily with the atmosphere, so heat transfer out of the well should be slowed. Some testing I did indicated that this might account for a difference of 1-2degC of the interior surface of the window on a cold night when the outside temperature is around 40degC and the inside temperature is around 62degC. While it’s not great, it’s also not insignificant. I expect that the real benefit will be that the wells do not fill with snow, but I’m not willing to leave one of them uncovered as an experimental control to find out.